A crucial decision about a tiny brewery

A crucial decision about a tiny brewery

overlooking the ocean

The challenge started with a small brewery, the closest one to the sea in Ibaraki. The spur for the decision was the 2011 Great East Japan Earthquake.

At the closest place in Ibaraki to the sea.

The northern part of Hitachi, Ibaraki Prefecture, facing the Pacific Ocean, includes the Kawajiri Coast, which shelters small swimming beaches and fishing ports. From there, start walking. One, two steps... and by the time you get to seventy steps, you’re at Morishima Sake brewery. The closest brewery to the sea in Ibaraki.

The obvious question to ask is, “If you're that close to the sea, can you still use well water?” We get this question a lot. But the water from the well on our site is an underground stream that flows down from the southern slopes of the Abukuma Mountains. It is hard water, which makes it good for sake. This brewery was beloved by locals for many years, and produced a label that featured the name of Yokoyama Taikan, the master of Japanese painting.

History carved into the Oya tuff brewery.

Morishima Sake brewery has a history of overcoming many difficulties. In 1945, during World War Two, our brewery and housing were destroyed by bombing. Koichiro Morishima, the fourth head, struggled to find Oya tuff, a sturdy, fireproof stone, but finally got enough to rebuilt the brewery and immediately restarted sake production.

Then 2011 happened. Another disaster struck. The Great East Japan Earthquake. While we were spared damage from the tsunami, the ground developed cracks right across our site, and hundreds of bottles awaiting shipping were smashed. Large cracks developed in the walls of our Oya tuff brewery as well.

A decision made for the future.

As aftershocks continued, sunlight poured into the brewery from the cracked stone. Our sixth head, Shoichiro, stood and stared at it. This major shock was only a few years after he had qualified to be a Nanbu Brewmaster, the first from Ibaraki, and was searching for a future for the brewery he had inherited.

He was suddenly faced with a harsh reality. It would be difficult to fully restore the stone brewery, and he considered relocation or even shutting the business down, but eventually he decided to repair it as much as possible, and continue to make sake on this site. And on the walls of that brewery, engraved with its history, he vowed to rebuilt Morishima Sake brewery, and make it better than ever.

The aim: a sake that would set a new standard

The aim: a sake that would set a new standard

for our brewery

This aim was the brand concept that launched a new era for our brewery. Through a process of trial and error, Shoichiro encountered many people and came to realize many things.

For the people who have believed.

During recovery from the earthquake, when Shoichiro was wondering what he should do for the future of the brewery, the idea he hit upon was to create our own brand, one that could equal the best labels of the brewery. He launched full-scale production of new sake brewing, along with the knowledge of brewing he learned at university and the techniques learned through training.

“I just want to make delicious sake. So I need to drive myself unstintingly, working harder today than I did yesterday, and harder tomorrow than I did today.” A lucky change happened with the new encounters and interactions with the alcohol shopkeepers and brokers both from Ibaraki and other prefectures who sensed the possibilities of this forward-looking stance. “If you make delicious sake, it’ll definitely sell.” For the people who believed this, Shoichiro continued to make improvements after improvements to ensure that we got results.

A life-changing encounter with a master.

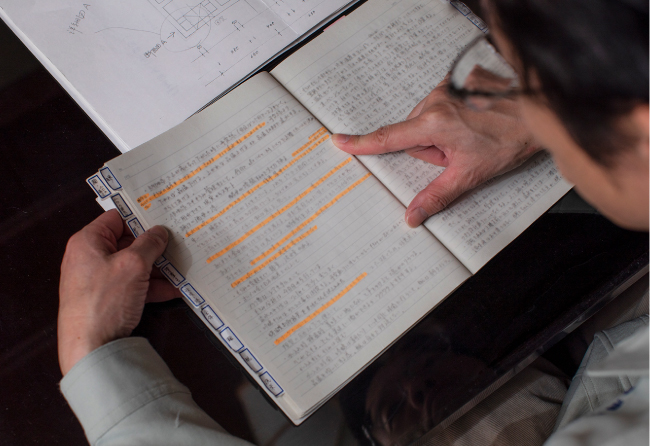

However, Shoichiro was still faced with days of making barely any progress. One alcohol shopkeeper gave him some harsh words: “You really think this is good? Are you serious about making sake?” Shoichiro had revised our methods time and again, read and re-read the literature, but as still unable to get the ideal flavor he dreamed of.

It was then that he encountered Master Kei’ichiro Katsugi, a leader in the industry. The Master had instructed numerous breweries, and Shoichiro hoped he could offer him some instruction as well. He had few hopes that he would bother with some tiny brewery in Ibaraki, but made his way to Saga Prefecture, and talked to the Master about his sincere dream of making sake. And eventually, he was finally able to get a chance for instruction.

Delicious sake is not made by one person.

What the Master taught Shoichiro was a way of making sake that had been refined based on his long years of experience. These were techniques that valued harmony with people’s efforts, faithful to the core, yet rational and based on logic. As Shoichiro began to understand each process, his questions were slowly answered. Being able to be taught the attitudes and ways of thinking needed to make delicious sake has become, in a similar way, a significant asset.

“Value your families.” One of the Master's statements that Shoichiro will not forget. Once the sake-brewing season starts, we all basically start living in the brewery. What makes this possible is the support of our families. Delicious sake is not made just by the brewmaster, but by his family, and by all the employees. The Master made Shoichiro realize this anew, providing him with a fresh perspective.

Finally time for shipping.

Finally time for shipping.

But the challenges do not end here

We needed to revise our entire equipment and methods, seeking the ideal taste without wavering. “Morishima” had to continue to evolve, pursuing ever-greater possibilities.

Questioning the taken for granted, re-evaluating the brewing equipment from scratch.

The path of creating a new brand is perilous. You must take a fresh look at everything you thought you knew about making sake, and continually question yourself every single day. The innovation you need the biggest resolve for is renewing your brewing equipment. This is what Shoichiro told himself.

We ordered square sieves to steam the rice to ensure it would be the perfect base for flavor. We also set up a mold chamber where we could control the temperature precisely, down to a range of a minute 0.3 degrees. We took particular care with the refrigeration facilities. We set up our press in the middle of our refrigeration room to ensure that the natural, delicate aromas that arise in the fermentation process would steep into the sake. We completely replaced our refrigerant tank and storehouse to ensure that people could drink our sake at its best, without losing any of the flavor of the pressed sake. “We want to make delicious sake.” That was our ideal. And before we knew it, we had replaced almost all our equipment. Never before in our history had Morishima Sake brewery brought in so much new equipment in such a short time.

Methods faithful to the core to create tastes suited for the times.

Shoichiro emphasizes several things to create our ideal taste. One of these is to express the deliciousness that allows you to taste the differing natures of each type of sake rice, the heart of sake. He carefully selected four types of rice: Omachi, Hitachi-Nishiki, Yamada-Nishiki, and Miyama-Nishiki. After much reflection, he decided on using 5% increments in polishing the rice.

Shoichiro also wanted to pursue what he alone could achieve to create a new type of sake. A beautiful clarity and fresh flavor that goes well with meal. And the right amount of acidity that cleanses the palate and allows you to continue drinking. The “taste suited for the times” he wanted is this. What he got into to achieve this was the true-to-its-core sake-making that Master Katsugi had shown him. From the perspective of going with food, he needed to choose traditional koji molds and yeasts, as they would create sake that is not too aromatic, not too sweet. Then he needed to take the time to understand each one of the universal processes of sake-making, learning them thoroughly, and only then could he create that taste. After refining this over and over, he finally achieved a “taste suited for the times” that he could truly be satisfied with.

Our brand name incorporates our commitment.

It took a decade from conception, but we finally reached the point of offering sake to our customers. The label Shoichiro chose for this, reflecting his resolve, is his surname, Morishima and features a stone, a fragment that fell from our Oya tuff stone brewery in the 2011 earthquake. This piece of rock is a valued symbol of the unbending spirit of Morishima Sake brewery, of how we will overcome any difficulty. The reason is twofold: so that Shoichiro never forgets his desire as a brewer to stir things up, like tossing a stone into a still pond, and so that the person drinking a glass of sake notices this “splash” of the new.

To a drink that lets you sense the depth of Japanese sake more than ever. While holding fast to our 150 years of history, Morishima will continue to tackle challenges and evolve.